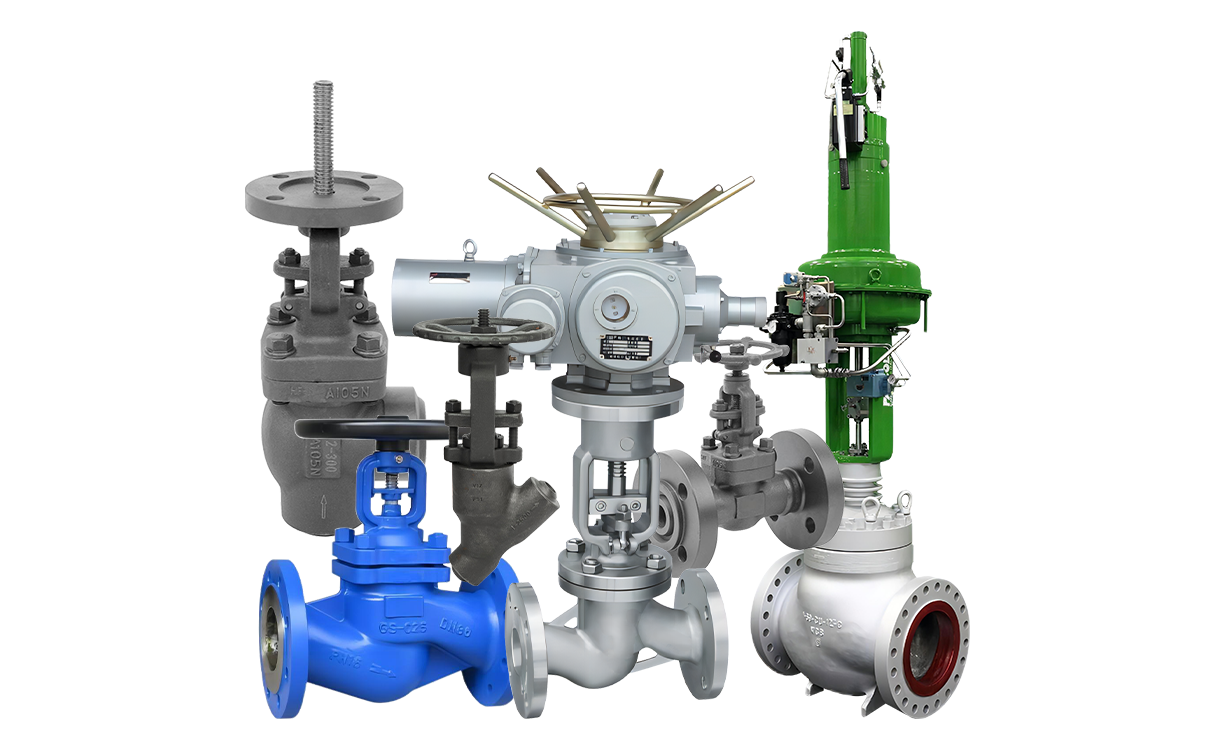

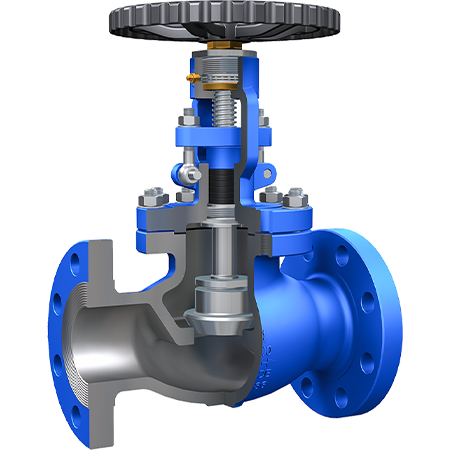

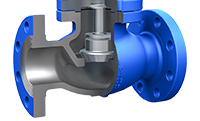

The valve stem opening or closing stroke is relatively short and has a very reliable disconnection function. Due to the movement pattern of the valve disc, the change of the valve seat opening is proportional to the valve disc stroke, so it is particularly suitable for flow regulation. Therefore, this type of gate valve is particularly suitable for cutting off, regulating and throttling.

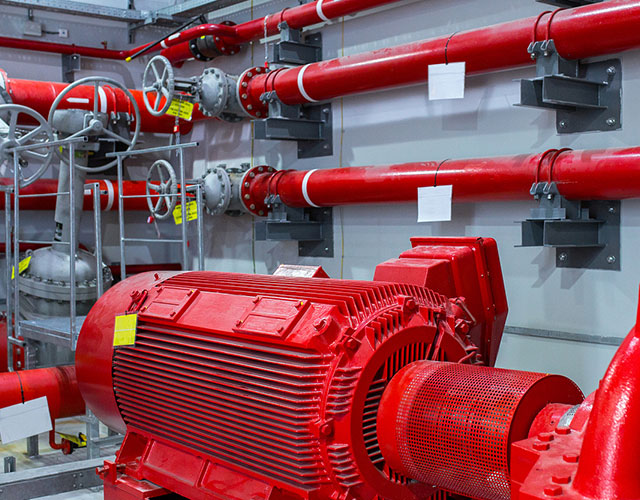

Globe valves are used in high-temperature and high-pressure media pipelines or equipment. Such as thermal power plants, nuclear power plants, petrochemical systems, high temperature and high pressure pipelines, etc. Pipes that do not require strict flow resistance. In other words, pressure loss is not a big consideration. There is flow adjustment or pressure adjustment, but the requirements for adjustment accuracy are not high, and the pipe diameter is small. It is used for industrial production of fertilizers and water supply and heating projects in urban construction.

Simple structure, convenient to manufacture and maintain.

The working stroke is small and the opening and closing time is short.

Good sealing performance, small friction between sealing surfaces and long service life.

Special design, very suitable for frequent operations and high pressure differences.

Diverse applications, suitable for on/off and throttling tasks.

Directional flexibility, Can be installed in various directions without affecting performance.

The fluid resistance is large and the force required to open and close is large.

Not suitable for media with particles, high viscosity, and easy coking.

Poor adjustment performance.

Size and weight: Generally larger and heavier than similar butterfly valves or ball valves.

Operating speed Compared with quick-acting valves, it takes longer to open or close.

Operating speed Compared with quick-acting valves, it takes longer to open or close.