-

Stainless Steel Wafer Vertical Lift Check Valve

Stainless Steel Wafer Vertical Lift Check Valve -

High-Pressure Stainless Steel Forged Flanged Lift Check Valve

High-Pressure Stainless Steel Forged Flanged Lift Check Valve -

Cast Carbon Steel Flanged Wafer Lift Check Valve

Cast Carbon Steel Flanged Wafer Lift Check Valve -

High-Pressure Self-Sealing Lift Check ValveHigh-Pressure Stainless Steel Forged Flanged Lift Check Valve

High-Pressure Self-Sealing Lift Check ValveHigh-Pressure Stainless Steel Forged Flanged Lift Check Valve -

Stainless Steel Wafer Vertical Lift Check Valve

Stainless Steel Wafer Vertical Lift Check Valve -

Stainless Steel Wafer Vertical Lift Check Valve

Stainless Steel Wafer Vertical Lift Check Valve -

High-Pressure Stainless Steel Forged Flanged Lift Check Valve

High-Pressure Stainless Steel Forged Flanged Lift Check Valve

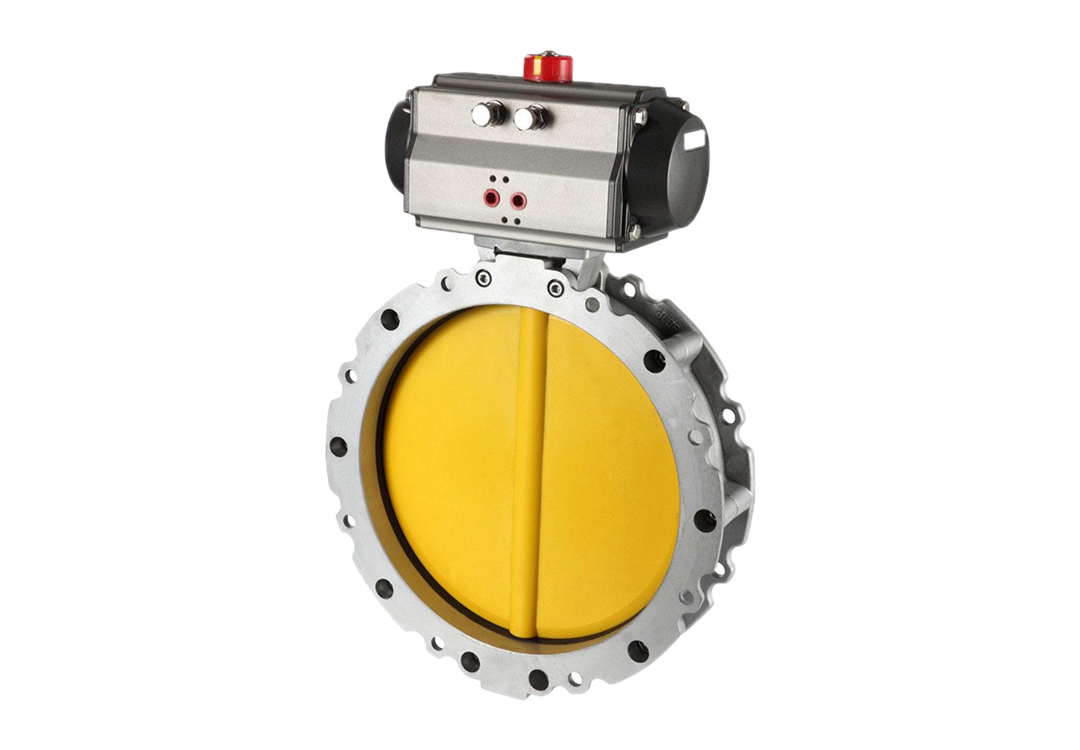

Lift Check Valves

Elevating standard valve capabilities, lift check valves offer a unique vertical disc lifting mechanism, ensuring precise flow regulation and effective prevention of reverse flow. These valves are engineered with high-quality materials, including robust brass and stainless steel, making them adaptable to various operational conditions. Their vertically oriented design is especially suitable for compact installations, providing reliable functionality with minimal wear. Lift check valves are integral in modern fluid systems, celebrated for their streamlined operation and consistent, low-maintenance performance.