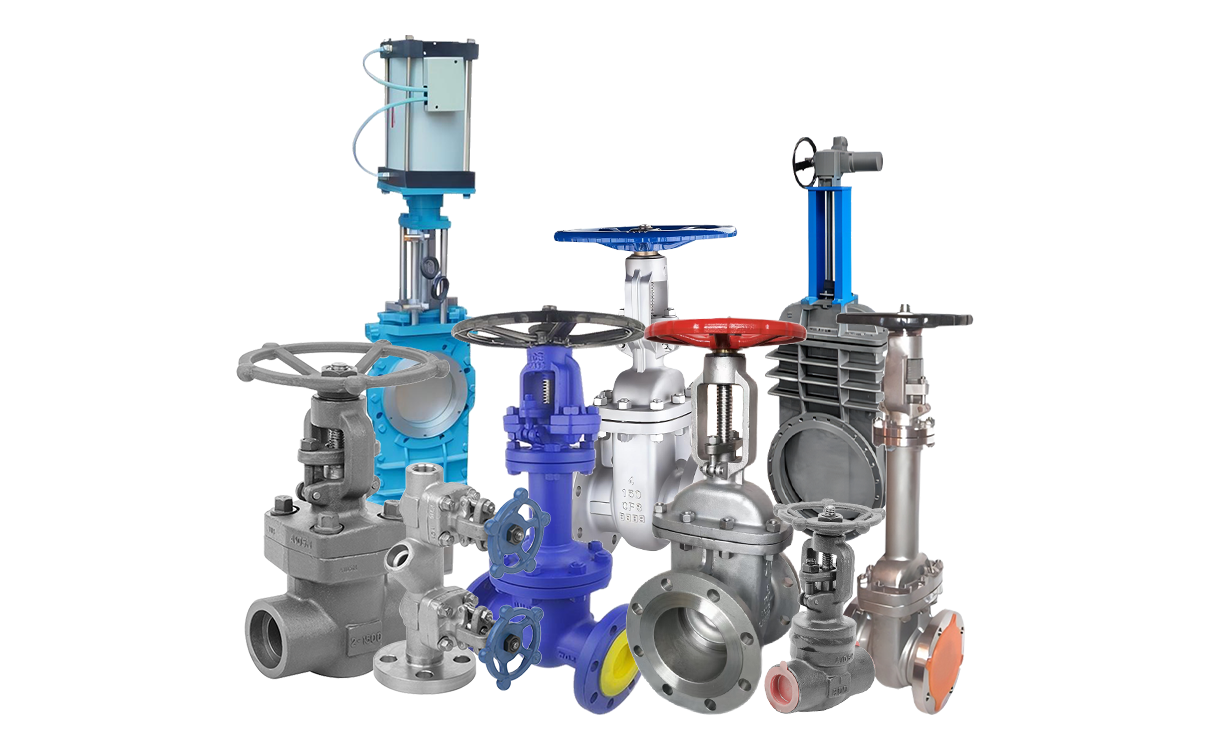

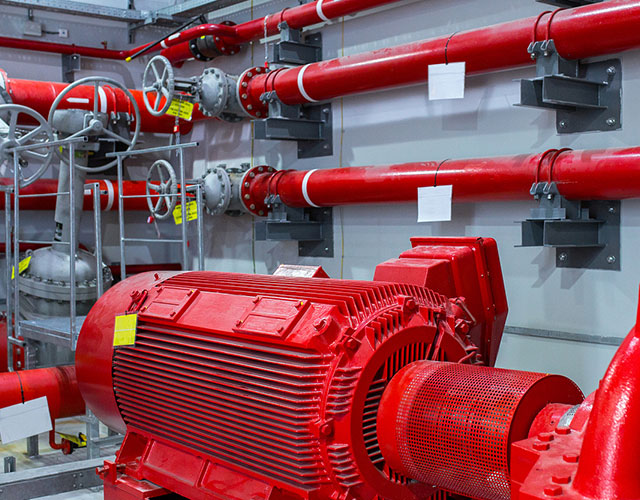

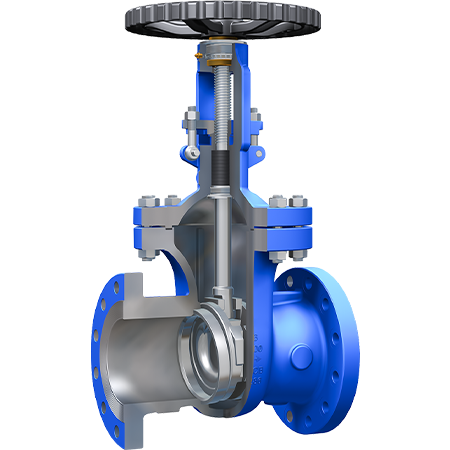

Compared with the stop valve, the valve stem of the gate valve has a longer opening or closing stroke, which can completely cut off the medium in the pipeline. The gate moves vertically in the direction of fluid movement, so the opening and closing resistance is small. It is usually used as a fully open valve on the pipeline. Or fully closed, it is one of the most common valves among industrial valves.

The gate valve has a simple structure and can generally only be fully opened or fully closed in the pipeline. It cannot be used for regulation and throttling. Especially among the gate valves, the knife gate valve can not only have a large diameter, but also has a lower price than other gate valves. This type of valve is much lower and is usually used in pipelines such as petroleum, chemical industry, natural gas, metallurgy, water and electricity.

The flow resistance is small, and the medium passes through the valve body pipeline in a straight line.

The opening and closing torque is small, and the movement direction of the gate valve is perpendicular to the movement direction of the medium.

The medium can flow in any direction from both sides of the gate valve without restriction, disturbance and pressure reduction.

The structural length is short. Since the gate valve is placed vertically in the valve body and the cut-off valve disc is placed horizontally in the valve body, the structural length is shorter than that of the cut-off valve.

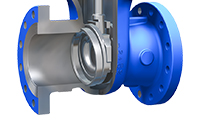

Good sealing performance, little erosion on the sealing surface when fully open.

When the valve is fully open, the erosion of the sealing surface by the working medium is less than that of the stop valve.

The shape is simple, the forging process is good, and it is widely used.

The sealing surface is easy to be damaged, and the friction of gate valve opening and closing and the erosion of the medium are received.

The switch time of gate valve is long, and the valve stem will rise when it is opened, which requires a certain space.

It can not be used as a valve to adjust the flow rate, and the ram is basically kept fully open or fully closed.