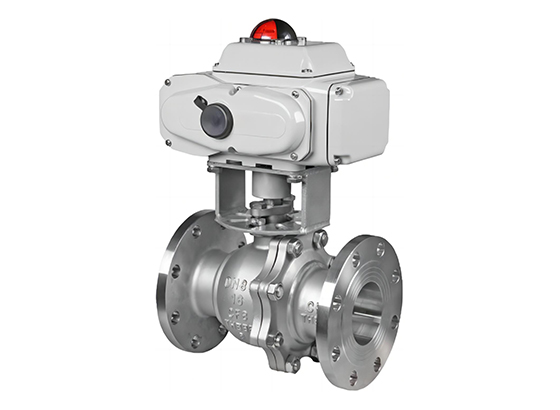

Why Choose Lipin's Two Piece Ball Valve

The body of Lipin's two piece ball valve adopts advanced technology, with high precision, fast opening and closing, and reliable sealing. A 90° switch positioning mechanism can be set, and locks can be added as needed to prevent accidental operation. The diameter of the ball is the same as the pipeline, which is easy to be disassembled and has a good sealing effect.

-

Good sealing

Non friction opening and closing completely solves the problem of traditional valves being affected by the friction between sealing surfaces.

-

Rich materials

Traditional carbon steel, chromium nickel iron alloy, and Monel alloy are all good choices for corrosion and high temperature resistance.

-

Widely applicable

Two piece ball valves can be found in the power industry, chemical industry, heating and air conditioning systems, etc.

-

Supreme quality

Lipin adopts high-precision machining centers, CNC lathes, and complete sets of equipment without paint spraying to ensure the highest production quality.

-

Diverse operating methods

The two piece ball valve can be manually operated or automatically controlled by electric, pneumatic, or hydraulic devices.