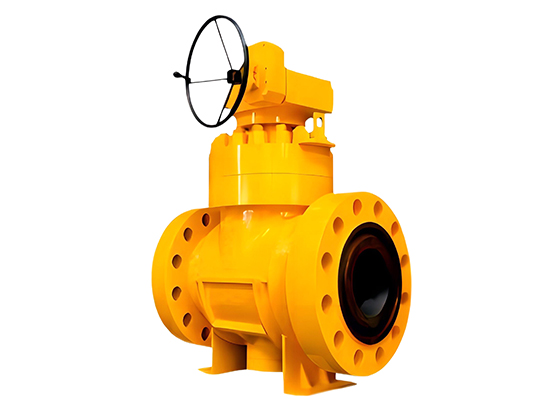

Why Choose Lipin's Top Entry Ball Valve

Lipin is a production, research and development, sales, service in one, specializing in the production of valves, pumps, non-regional group of companies. Lipin's top entry ball valve has the advantages of compact structure, good sealing performance, low flow resistance, fast opening and closing speed, strong corrosion resistance, long service life, safe and reliable work, and easy maintenance.

-

Installation without removing the ball

The ball can be installed and maintained without removing the valve body, which largely saves time and labor costs, and reduces the steps of depressurization and spitting, which reduces the problem of safety risks.

-

Various materials available

Available in cast steel, stainless steel, cast iron and ductile iron as well as alloy materials, you can consider a variety of factors and we can meet your different industrial needs.

-

Applicable to all areas

Lipin's top entry ball valves are well applied in many industrial environments such as oil, gas, chemical industry, electric power and nuclear power.

-

Commitment to quality excellence

Strict selection of high quality raw materials to ensure product reliability. Each top entry ball valve passes strict tests and quality control in order to show its superior working characteristics.

-

Multiple control

According to your specific industrial environment needs, we can provide you with a variety of control methods, including manual operation, transmission control, pneumatic control, electric control, pneumatic-hydraulic combination drive and electro-hydraulic combination drive, etc. for your choice.

-

Top service team

Our company's one-stop valve solution helps our customers solve many concerns and troubles. Not only that, we also provide a two-year warranty for our products. If you are interested, you can contact us to get a plan.