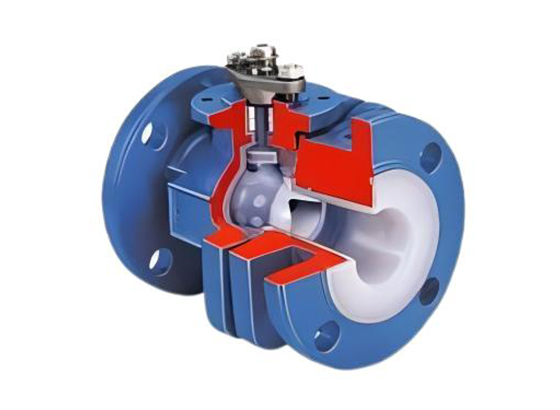

The mold for the PTFE lined ball valve is made from precision castings, which are not easily deformed during the forging process. The mechanism is high-density, the surface is smooth and smooth, and the design is beautiful and generous. The metal surface before the inner lining has undergone mechanical processing or sandblasting treatment, and oil removal (degreasing) to solve the problem. The first contact part between the sphere and the sealing seat is made into a cantilever lip, which creates a buffer zone between the valve body and the sealing ring. This can automatically compensate for the wear of the valve seat, rapid changes in temperature and pressure, and leakage caused by plastic deformation; Improved sealing performance and extended service life.