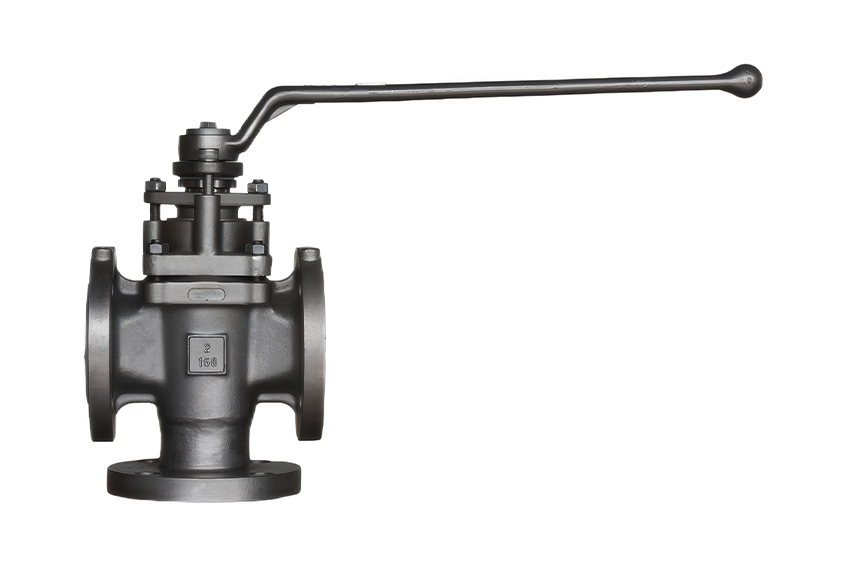

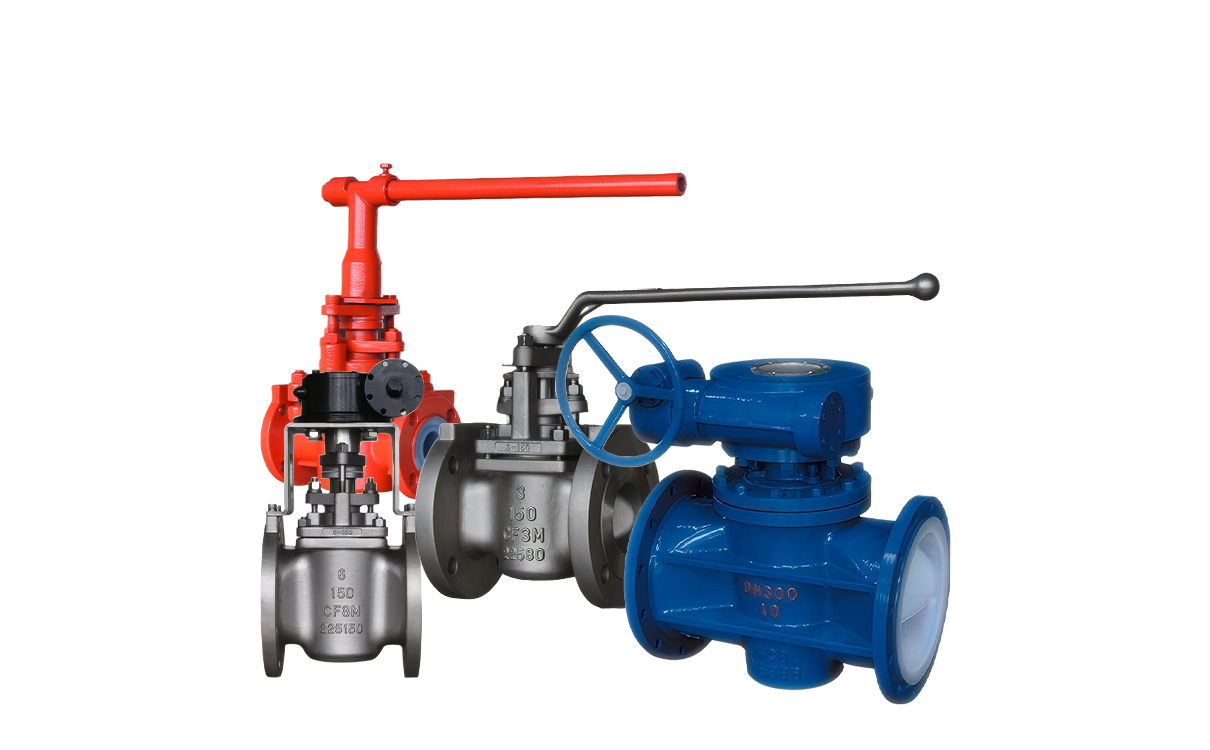

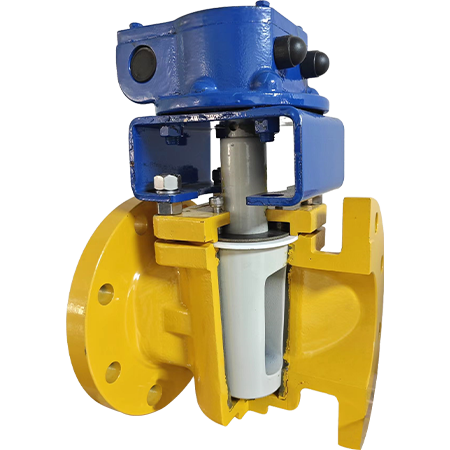

Manual plug valves work by rotating the plug to open or stop the flow of fluid. Plug valves are easy to operate, compact and can be manufactured in larger sizes. They are reliable, simple in structure and easy to maintain. The sealing surface and cock are often in a closed state and are not easy to be eroded by the medium, so they are widely used in various industries.

Because plug valves typically use materials such as rubber, nylon and teflon as seat seals, the choice of seal materials determines the applicable temperature range. Therefore, when selecting the structure and performance of the plug valve, it is necessary to consider its fire resistance and applicability to the petroleum, chemical, metallurgical and natural gas industries.

Low Flow Resistance: Offers minimal flow resistance, facilitating quick opening and closing.

Effective Sealing: Can achieve complete sealing over a broad range of pressures and temperatures.

High Pressure Tolerance: The plug can withstand significant pressure differences during operation.

Compact and Lightweight: Features a compact structure that is easy to handle and install.

Symmetrical Design: The symmetrical valve body effectively manages pipeline stress.

Protected Sealing Surface: When fully open or closed, the sealing surfaces are shielded from the medium, preventing erosion.

Temperature Sensitivity: The operating temperature is limited by the materials used for the valve seat.

Limited Adjustment Capability: Provides less precise flow control compared to globe valves.

Temperature Impact: Sealing performance may be affected by temperature variations.

Wear and Tear: Friction between the plug and the valve seat can lead to wear over time.

Higher Cost: Generally more expensive than other valve types.

Space Requirements: Requires longer structural length and more space for installation in pipelines.