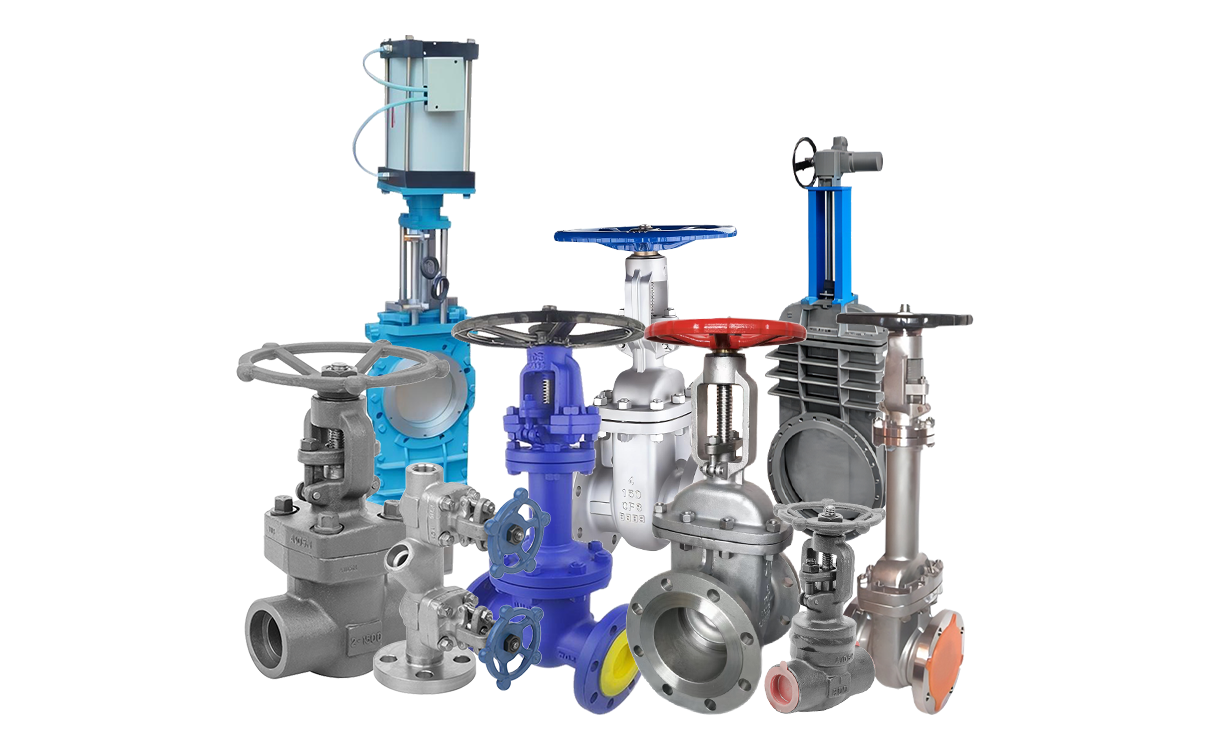

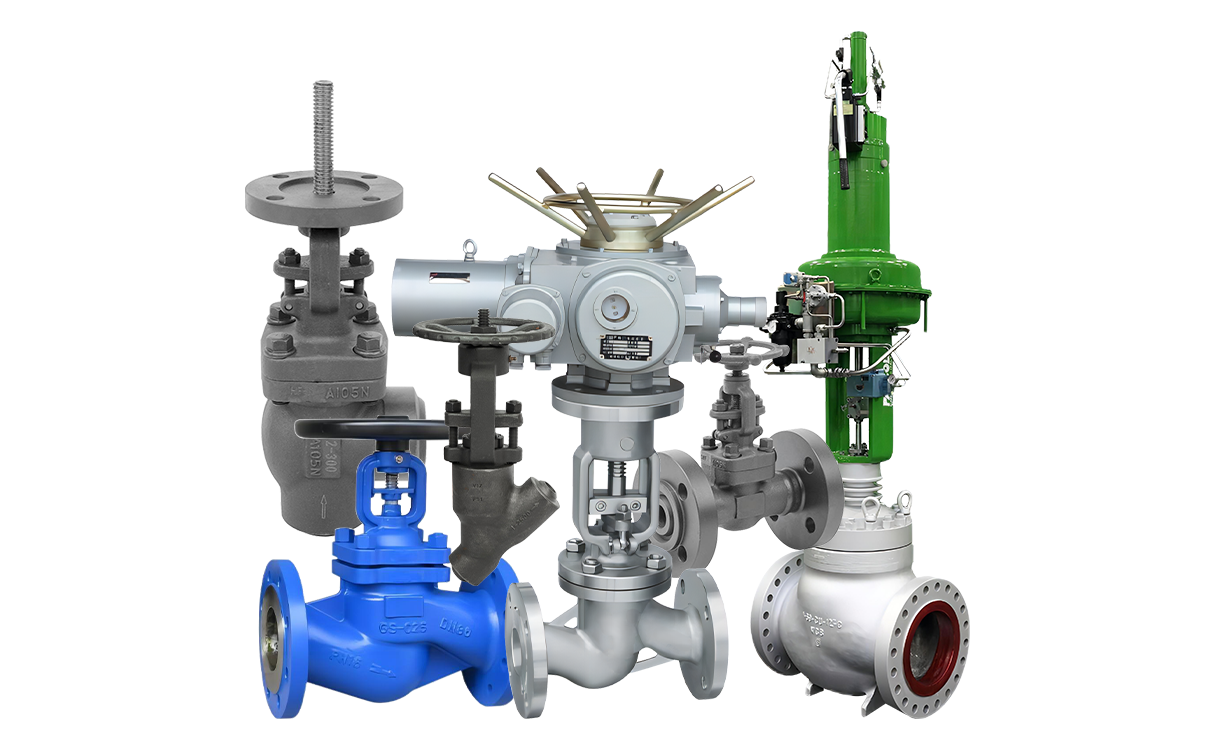

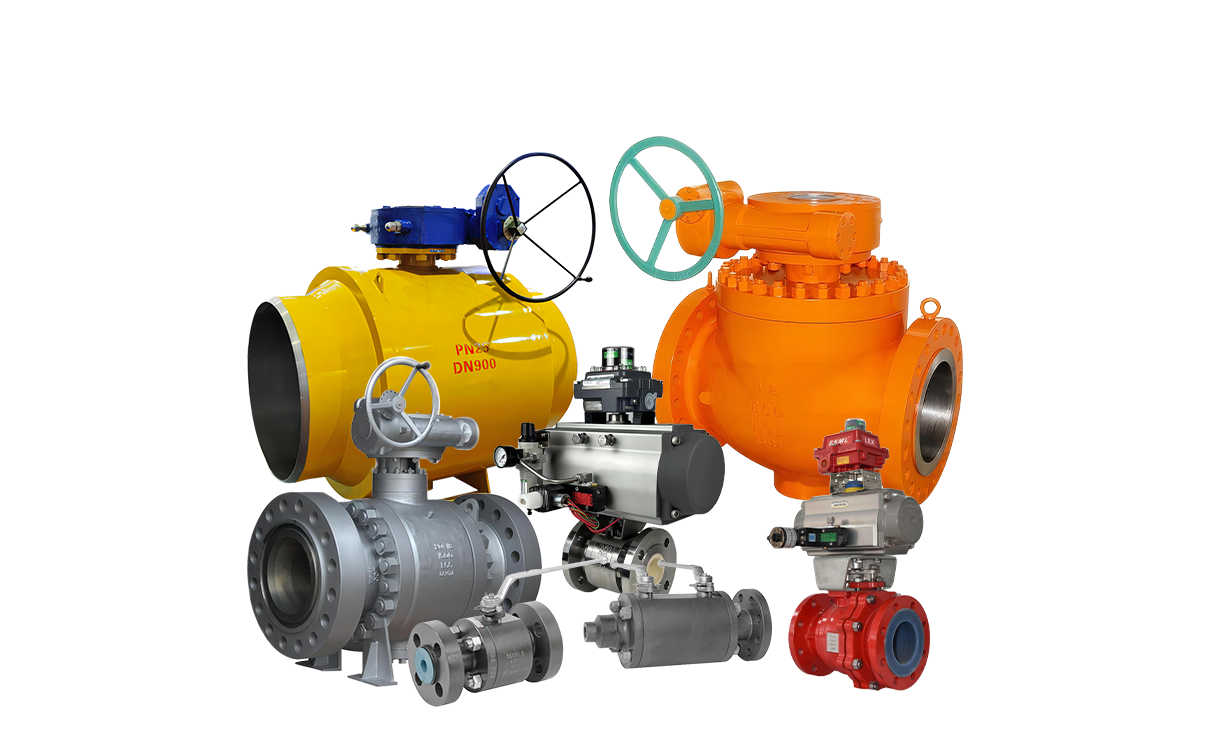

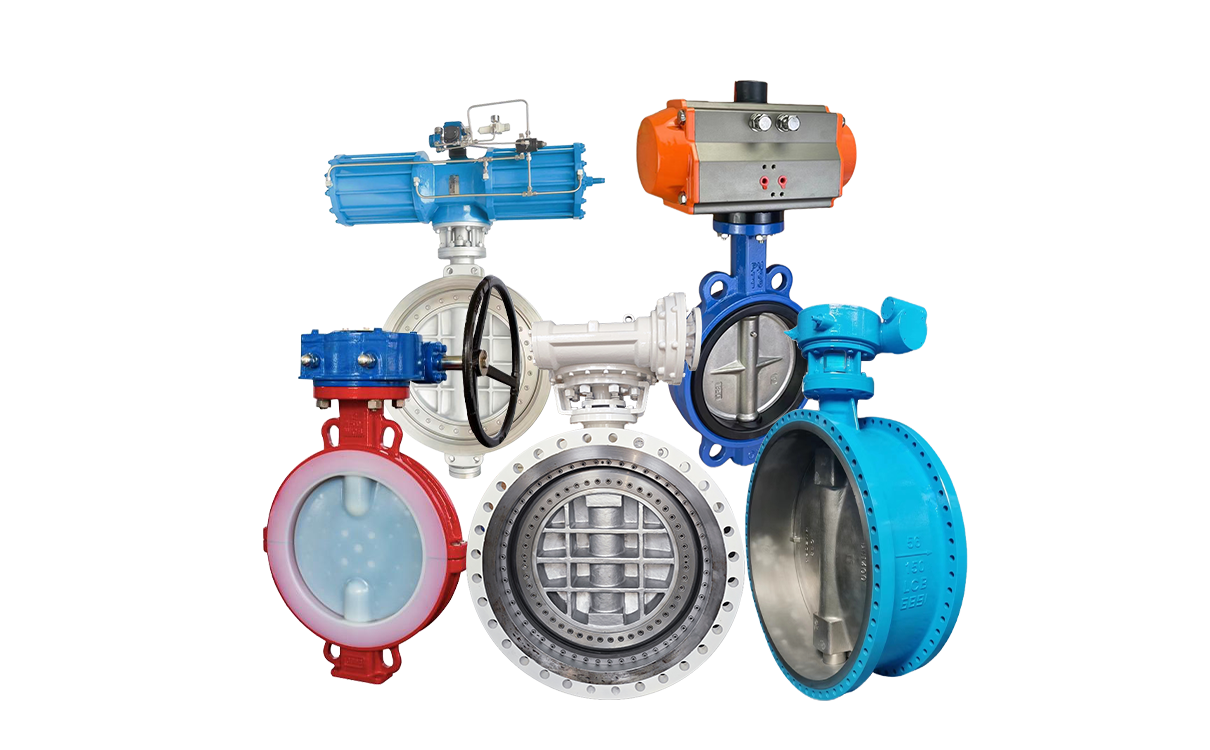

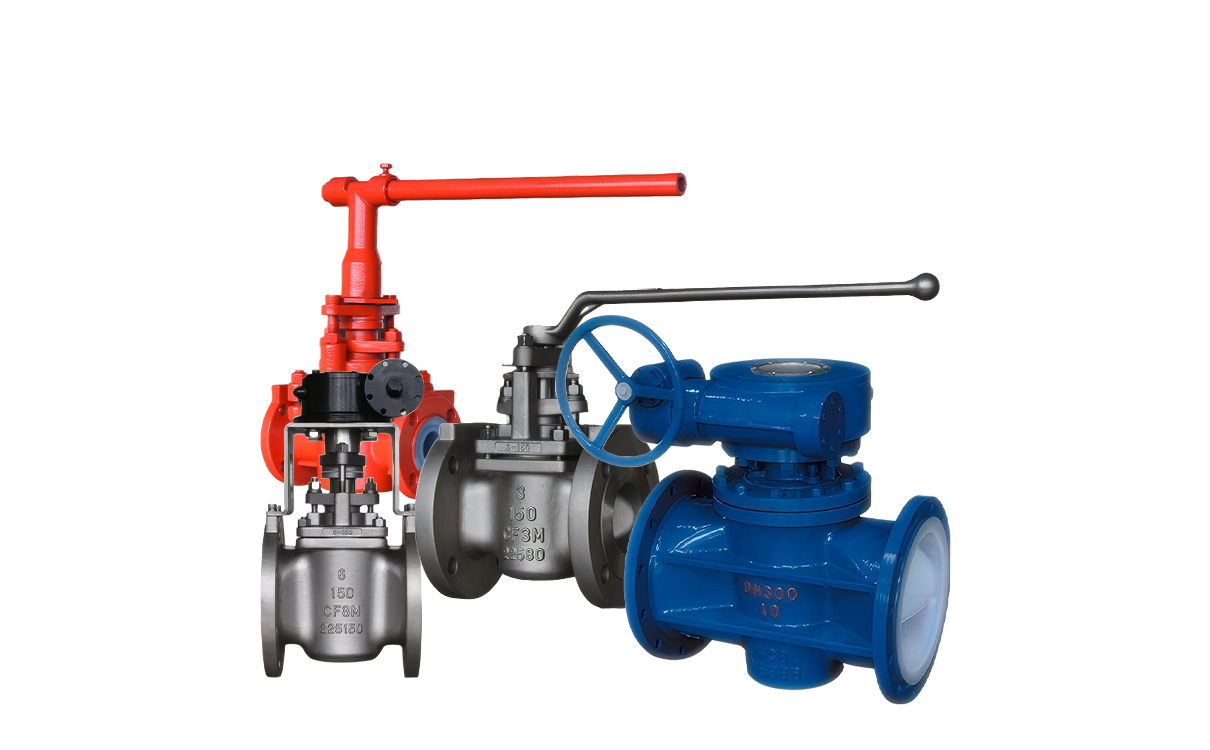

Zhejiang Lipin Valve Co., Ltd. has 36 years of production experience, leading products are gate valve, globe valve, butterfly valve, ball valve, check valve, regulating valve, pressure reducing valve, diaphragm valve, plug valve, trap valve, power station valve and so on more than 80 types of valves, for all walks of life to provide a one-stop solution for fluid control.

Lipin has four major production centers, including the existing casting workshop, forging workshop, special valve workshop, and an industrial pump workshop under construction, which is expected to reach 20,000 tons of annual output value after completion. The valves we produce are widely used in all walks of life, including petroleum, chemical, hydropower, energy and other different fields. Meet the requirements of various complex working conditions.

We provide a one-stop solution covering our existing 6 valve types, including gate valve, globe valve, check valve, ball valve, butterfly valve, safety valve, we are constantly adding different types of valves to our solution, through continuous innovation, the current stage of visual production, just open the computer or mobile phone, by connecting our internal system, You can follow the production progress of your valve in real time.

The valves produced by our factory can accurately control the fluid in the pipeline in a variety of complex environments, and our valves play an excellent role while also ensuring the safety of the pipeline to a great extent. Our one-stop valve solutions for customers from selection to production, from assembly to delivery, as well as some after-sales service after valve installation, we will keep close contact with our customers to ensure that the performance of the valve can be optimized.

Lipin valve through continuous technological innovation, so as to improve the durability of our products and manufacturing level, in the industry through excellent product quality to enhance the popularity of Lipin valve, to provide customers with fast one-stop service is famous, as a pioneer in the valve industry.

As a manufacturer specializing in the production of valves at home and abroad, Lipin has a number of international certification standards and can produce valves of various specifications and grades. The following are several common design standards and specifications in the industry.

ANSI (American National Standards Institute) was founded in 1918 and is the official standardization organization of the United States. As one of the largest organizations in the world, ANSI is responsible for coordinating and publishing official standards in the United States and plays an important role in ISO (International Organization for Standardization).

API (American Petroleum Institute) was founded in 1919 and represents the U.S. oil and gas industry. API has developed a series of industry standards related to oil and natural gas, which are widely adopted around the world and cover exploration, production, transportation and processing.

ISO (International Organization for Standardization) was founded in 1947. It aims to promote global trade and cooperation and formulate unified global standards that are powerful and widely adopted in various industries and fields. It has established various authoritative certification systems with universal adaptability in the context of many promulgation and implementation center levels or regional levels, including quality management, environmental management, and product specifications.

DIN (German Institute for Standardization) is Germany's national standardization organization, founded in 1917. DIN has developed many standards widely used in Germany and Europe, covering various fields such as engineering, materials and technical specifications.

JIS(Japanese Industrial Standards): Defines precise requirements for valve design, dimensions, materials, manufacturing, and performance tests across various valve types. These standards are widely adopted in Asia, ensuring compliance beyond Japan's borders.

GOST (Russian National Standards): Governs valve design, materials, manufacturing, and performance benchmarks, ensuring adherence to safety and quality specifications within Russia and former Soviet Union nations. GOST standards are crucial in regulating valve production, guaranteeing compliance and quality.

its working temperature from ultra-low temperature -269℃ to high temperature 1200℃, and even up to 3430℃;

The working pressure ranges from ultra-vacuum 1.33×10-8Pa (1×10ˉ10mmHg) to ultra- high pressure 1460MPa; The diameter of the valve is from 1mm to 6000mm, and even up to 9750mm.

Valve materials from cast iron, carbon steel, developed to titanium and titanium alloy steel, as well as high-strength corrosion resistant steel, low-temperature steel and heat- resistant steel valves.

The driving mode of the valve has been developed from manual to electric, pneumatic, hydraulic, until program control, numerical control, remote control and so on.

The processing technology of the valve is also from ordinary machine tools to assembly lines and automatic lines.

According to the medium characteristics, working pressure and temperature, select the valve body material, sealing surface material.

According to the working pressure and temperature of the valve body material and medium choose nominal pressure level.

According to the nominal pressure, medium characteristics and temperature, select the sealing surface material. Make its maximum operating temperature not lower than the medium operating temperature.

According to the calculation value of the pipe diameter, the nominal size is determined. Under normal circumstances, the nominal size of the valve is the diameter of the pipe.

According to the use of the valve and the requirements of the production process conditions, choose the drive mode of the valve.

According to the connection method of the pipeline and the nominal size of the valve, choose the connection form of the valve.

According to the nominal pressure, medium characteristics and operating temperature and nominal diameter of the valve, select the type, structure and model of the valve.