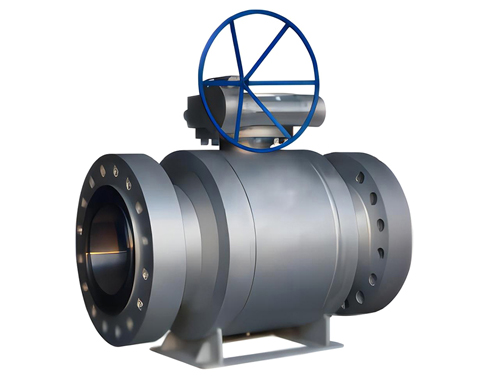

Why Choose Lipin's Fully Welded Ball Valve

Lipin fully welded ball valves are manufactured by pressing seamless steel pipes. This manufacturing method is just right to maintain good sealing of all welded ball valves. The reason is that it is difficult to press seamless steel pipes, and it is impossible to ensure uniform stress after installation. Because the installation environment of the fully welded ball valve is inspected before manufacturing, and the same material as the piping system is selected to suppress the fully welded ball valve, so after the manufacturing is completed, the fully welded connected valve is made of the same material as the piping system, so The force is uniform, so there is no failure of the valve to be damaged due to uneven stress. Valve leakage is greatly reduced.

-

Fully welded sealing design

The unique full welding process welds all the gaps on the surface to prevent internal and external leakage through the gaps.

-

A variety of materials to choose from

Beyond traditional carbon steel, we offer avant-garde options such as Inconel and Monel. Such materials serve as a bulwark against corrosion, especially in challenging environments.

-

Wide range of applications

Whether it is used in thermal oil, thermal power plants or gas output, the fully welded ball valves produced by Lipin can be perfectly adapted.

-

The quality is high enough

For each process, we are operated by specialized welders. Each welder needs to hold a welding certificate to work. The full welding machine also uses the most advanced CNC machine to ensure the accuracy of processing.

-

Multiple operating modes to choose from

electric, pneumatic, hydraulic, manual operation, and gearbox drive is the most popular option.

-

Top service team

Our company's one-stop valve solution helps our customers solve many concerns and troubles. Not only that, we also provide a two-year warranty for our products. If you are interested, you can contact us to get a plan.