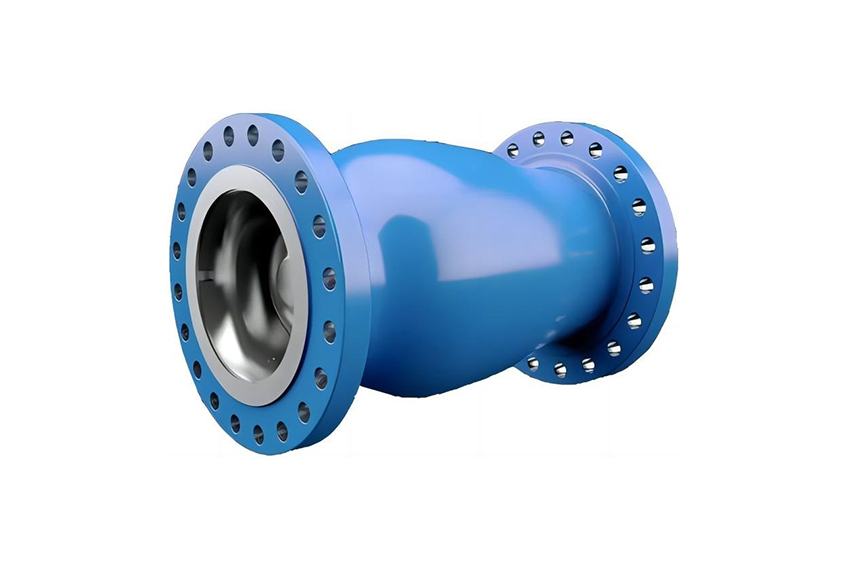

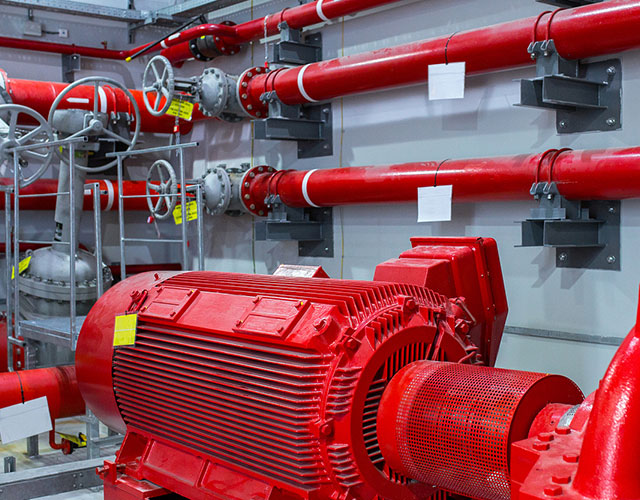

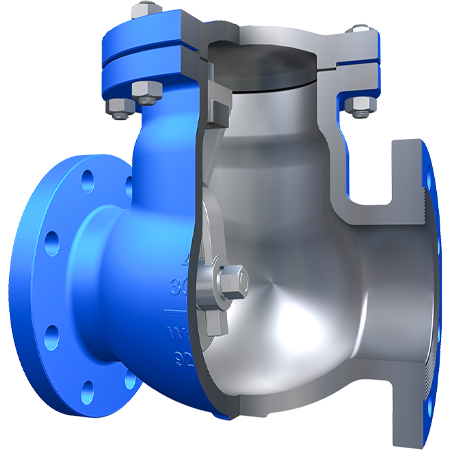

Within the realm of flow control, check valves carve a niche of their own by automatically permitting fluids to flow in a single direction, preventing reverse flow. These valves are distinguished by their swift response and simplicity of design, often lacking a handle or stem.

Overall, industrial check valves are an essential component in protecting the integrity and efficiency of fluid control systems. Their ability to prevent reverse flow seamlessly while offering a durable and low-maintenance solution makes them a vital fixture in any industrial setting.

Non-Return Function: Prevents backflow and protects the system from reverse flow damage.

Automatic Operation: Operates without manual intervention and does not require external power.

Simple Design: Fewer moving parts compared to other valve types, which reduces maintenance.

Quick Response: Designed to close rapidly to minimize the risk of flow reversal and water hammer.

Compact Size: Generally smaller than globe valves, making them ideal for space-constrained applications.

Versatile Installation: Can be installed in horizontal or vertical lines with upward flow.

Durability: Can handle high-pressure systems due to robust design.

Low Maintenance: Less wear and tear during operation due to fewer moving parts.

Flow Interruption: Can cause a slight drop in pressure due to the valve’s cracking pressure requirement.

Potential for Slamming: Quick-closing designs may lead to slamming and consequent water hammer.

Limited Throttling Capability: Not suitable for applications requiring flow regulation.

Sensitivity to Debris: Can become clogged with particulates, leading to failure to close.

Directional Flow: Only allows flow in one direction, limiting flexibility in some systems.

Less Feedback: Does not provide position indication since operation is automatic and relies on flow conditions.

Sealing Challenges: In some designs, ensuring a tight seal when closed may be challenging, especially as wear sets in.

Dependency on Flow Velocity: Requires a minimum flow velocity to operate effectively, which may not be met in low-flow conditions.