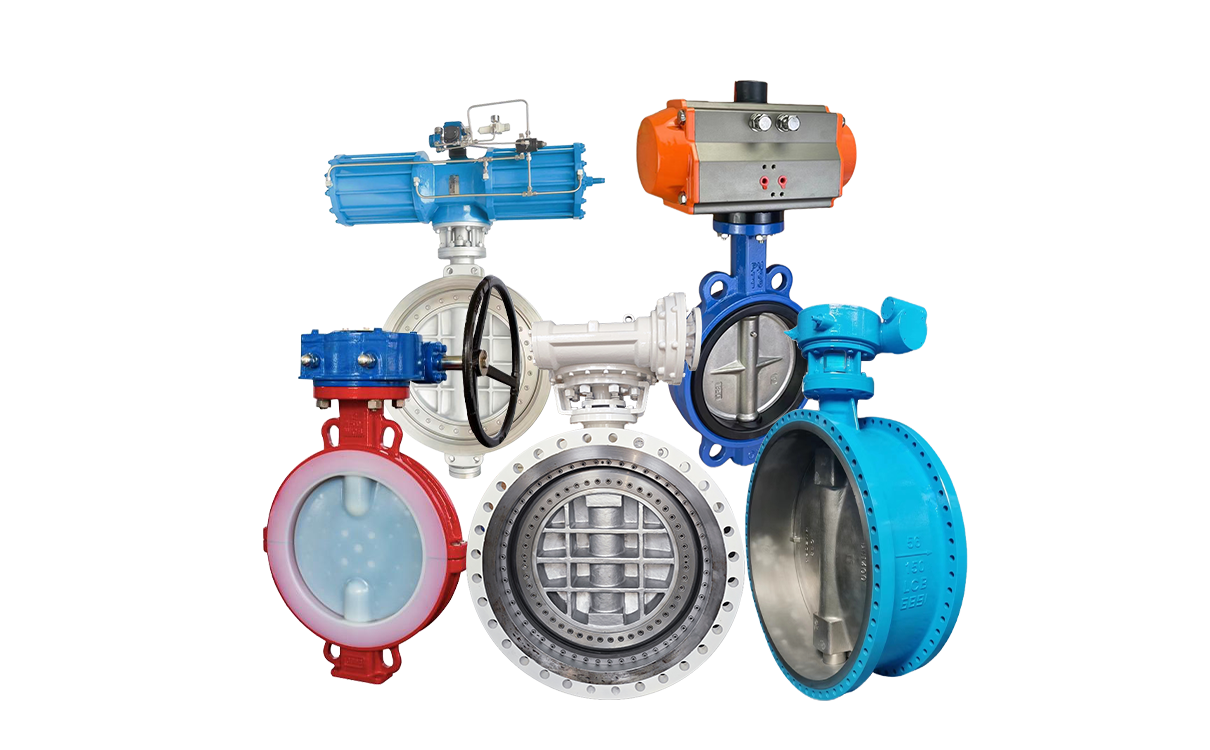

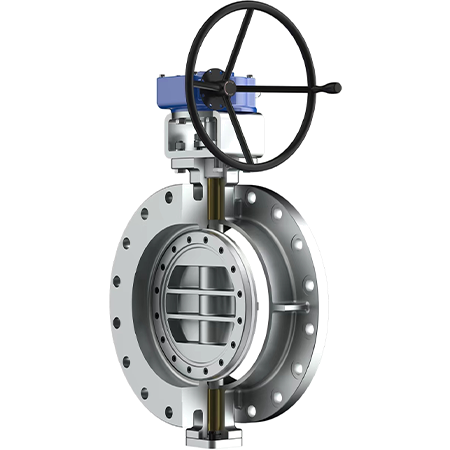

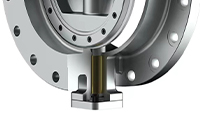

In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis with a rotation angle between 0° and 90°. When rotated to 90°, the valve is fully open. At this time, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated through the valve is very small, so it has good flow control characteristics.

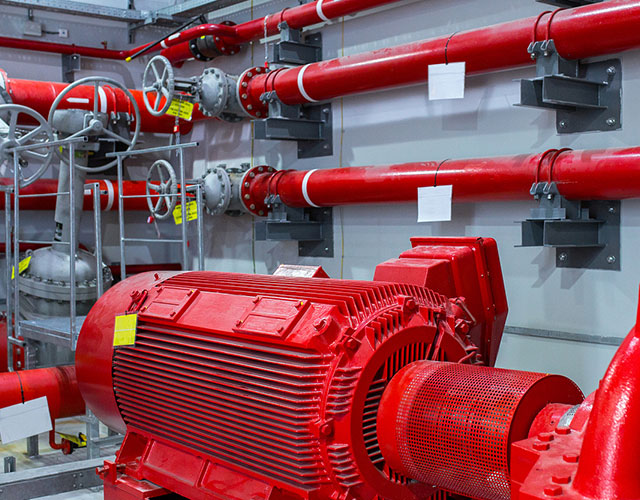

A common application of butterfly valves is water conservancy projects. It is also used in pipelines transporting various corrosive and non-corrosive fluid media in engineering systems such as generators, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting, power generation and environmental protection, and is suitable for flow regulation. Since the pressure loss of butterfly valves in the pipeline is relatively large, about three times that of gate valves, when selecting butterfly valves, the impact of pressure loss on the pipeline system should be fully considered.

The opening and closing torque is small and convenient, the structure is compact, and it is suitable for large diameters.

Better sealing in low pressure environment

Can pass through media containing particulate matter without clogging

Simple structure, easy to install and flexible to operate

Various types of butterfly valves can be customized to achieve different usages

High efficiency in regulating water volume and water level

Due to limitations of structure and sealing materials, it is not suitable for use in high temperature and high pressure pipelines.

The sealing performance is worse than that of ball valves and globe valves, and the sealing requirements are not high.

Compared with the ball valve with 0 flow resistance, there is a valve disc as resistance

The flow adjustment range is not large