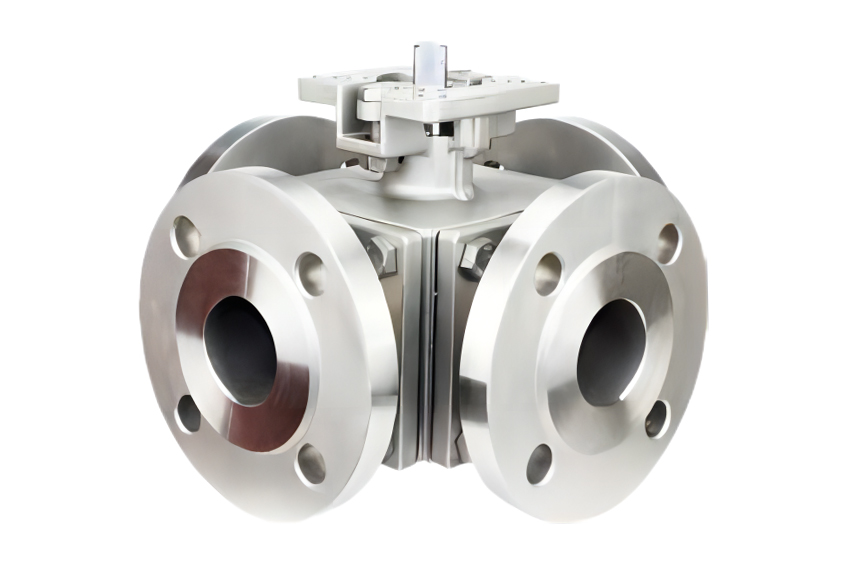

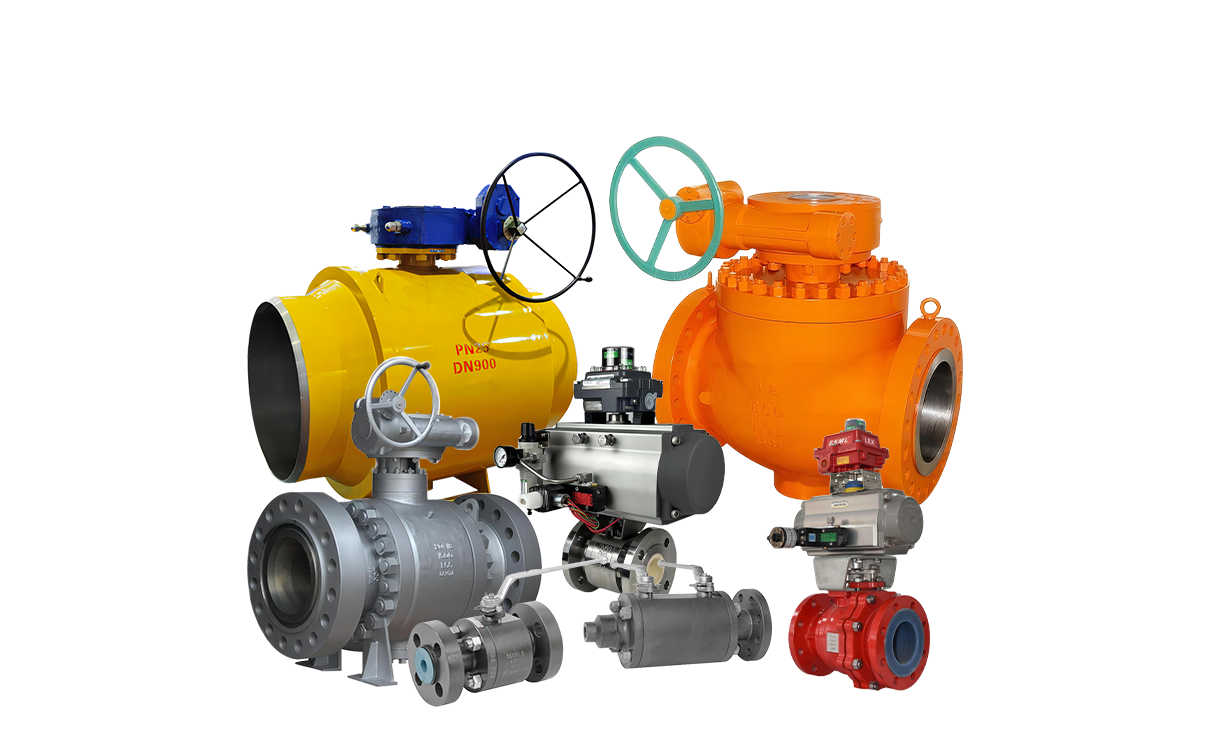

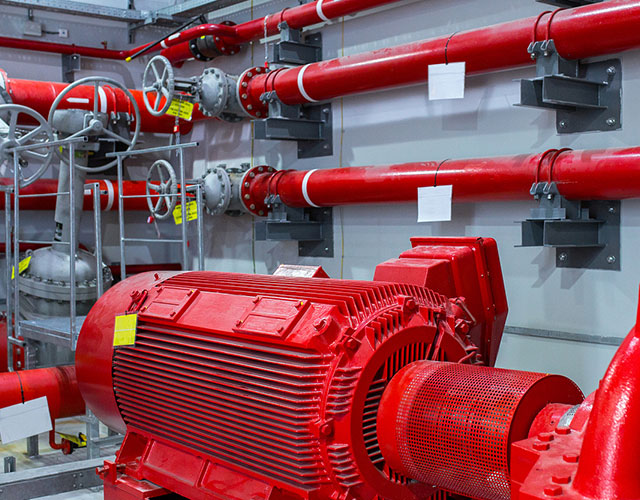

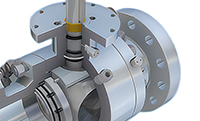

The working principle of the manual ball valve is to make the valve open or blocked by rotating the spool. Ball valve switch light, small size, can be made into a large caliber, reliable sealing, simple structure, easy maintenance, sealing surface and sphere are often in a closed state, not easy to be washed by the medium, in various industries have been widely used.

Because the ball valve usually uses rubber, nylon and polytetrafluoroethylene as the seat sealing ring material, the material of the seat sealing ring determines the applicable temperature, so in the selection of the structure and performance of the ball valve, it is necessary to consider the fire resistance and fire resistance of the ball valve, which is suitable for petroleum, chemical industry, metallurgy, natural gas and other fields.

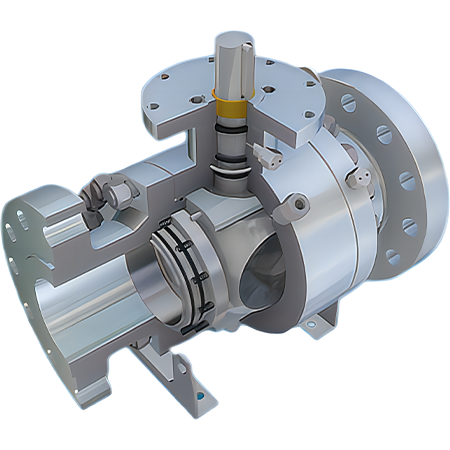

Has the lowest flow resistance (actually 0),Quick opening and closing can be achieved

Complete sealing can be achieved within a larger pressure and temperature range

The closing part can withstand the high pressure difference during closing

Compact structure and light weight

The valve body is symmetrical and can well withstand the stress from the pipeline.

When fully open and fully closed, the sealing surface of the ball and valve seat is isolated from the medium and will not erode the sealing surface.

The working temperature is determined by the material of the valve seat

Its adjustment performance is worse than that of the globe valve

Affected by temperature, sealing performance may be affected

There is friction between the ball and the valve seat and is prone to wear.

Price Relative to other types of valves, the price of ball valves is usually higher

Long structural length and large reserved space for pipelines